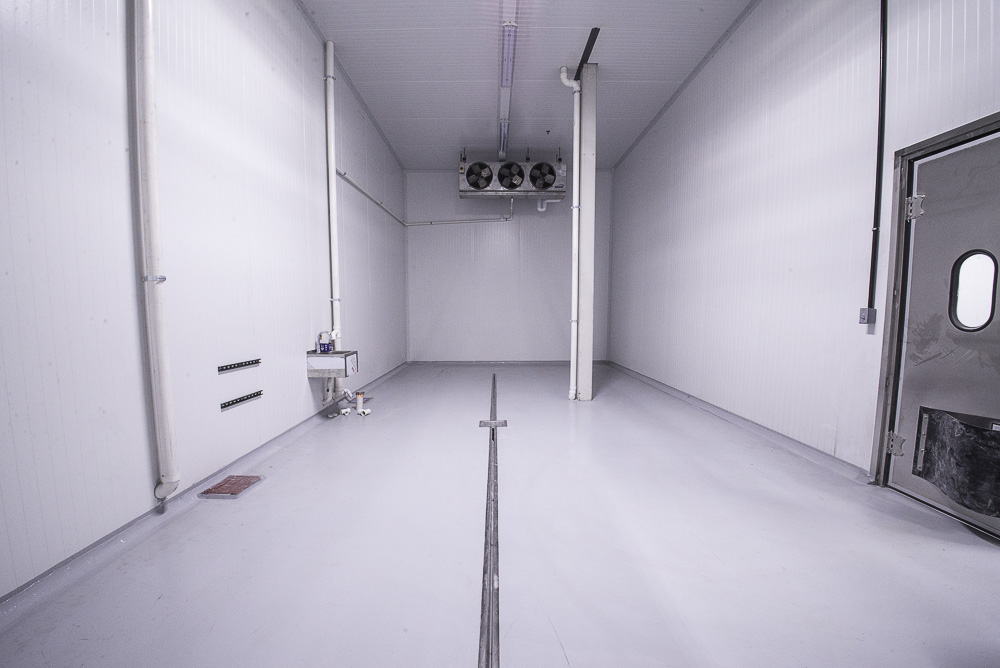

Cold storage facilities and commercial refrigeration come with unique challenges when it comes to insulating them properly. Using the right materials and refrigeration equipment is essential to maintain consistent cool temperatures, protect stored goods, ensure energy efficiency and minimise operating costs. The key challenge to overcome is thermal transfer, which is energy and heat that enters a building through the floor, walls and roof.

Most classic flooring options like concrete perform poorly when it comes to maintaining indoor temperatures. The right type of floor insulation can combat this, preventing heat transfer, lowering energy bills and making it easier to maintain the required refrigeration levels. Technonicol’s Carbon extruded polystyrene XPS foam insulation is ideal for this.

Thermal Insulation Design for Cold Storage Buildings

Insulation and refrigeration are two equally important components when it comes to maintaining the proper, consistent temperature required in a cold storage facility. Without the right design considerations, energy costs will be high and warm pockets will exist within the facility, potentially compromising stored goods. The type of insulation used in cold storage buildings has evolved over time as technology has advanced.

Expanded polystyrene EPS foam is commonly used. However, XPS foam is now the preferred option for multiple reasons. It’s stronger, more resistant to moisture and can be used continuously to prevent thermal transfer beneath the floor. EPS loses its insulating properties when exposed to moisture and is compressed, both of which are likely when installed under flooring in cold storage applications.

Insulating Against the Heat

In residential properties, insulation is usually installed with the key goal of keeping heat in. In cold storage facilities and commercial refrigeration, the goal is obviously to keep heat out. Cold storage buildings absorb more heat than a typical building. Effective insulation is there to decrease the load on the refrigeration equipment and reduce energy usage.

XPS Foam Insulation – Ideal for Cold Storage Flooring

Unlike EPS, XPS foam insulation doesn’t have any tiny voids or spacing between the cells due to the continuous extrusion production process. This is what makes it better at reducing heat transfer and repelling water absorption and water vapour transmission. This makes XPS foam unique in being able to maintain low thermal conductivity in the presence of a lot of water. This is essential considering the higher presence of moisture and condensation in cold storage spaces.

Carbon XPS foam insulation is lightweight and easy to work with, adaptable to various kinds of floor constructions. It’s strong enough to insulate load bearing floors. A closed-cell construction means XPS foam can withstand freeze-thaw cycles that ground floor insulation is often exposed to. This helps maintain the R-value of the insulation as well as preventing premature deterioration.

The Importance of Compressive Strength for Floor Insulation

Compressive strength is another important consideration when it comes to flooring insulation. In cold storage applications, it will usually need to withstand the weight of stored goods, racking assemblies and dynamic weight from heavy vehicles. Insulated concrete slabs are common in cold storage facilities. These slabs and the layers below it must be capable of supporting heavy loads.

Uniformly distributed closed cells in XPS foam gives it superior compressive strength characteristics when compared to EPS. This makes it a reliable and long lasting solution when used in cold storage floors that must withstand heavy loads. Technonicol’s Carbon Solid XPS foam is ideal for this particular application as it offers a minimum compressive strength of 500kPa. This makes it more than capable of accommodating higher floor loads in cold storage facilities.

Insulating Cold Storage Floors with Technonicol XPS Foam

Technonicol’s Carbon XPS foam range comes in a variety of sizes, thicknesses and compressive strengths to meet the demands of flooring insulation in cold storage facilities. It is:

- Extremely durable

- Highly resistant to moisture

- Guaranteed to have low, stable and predictable thermal conductivity

- Able to withstand temperature changes and freeze/thaw cycles.

At Plastek, we have extensive experience consulting and supplying these XPS foam products, helping to optimise projects by providing the ideal solutions. We can recommend the right Carbon XPS foam product for your specific project, ensuring a functional and high performance solution for your building.

Related Questions

Why is XPS foam a better insulator than EPS foam?

EPS insulation is produced by expanding polystyrene beads whereas XPS is produced by extruding beads through a die. The production process behind EPS tends to result in the beads expanding unevenly, leaving tiny gaps. These gaps conduct heat due to the air and moisture that gets inside them. XPS foam is free of any gaps/voids, meaning it repels water and limits heat transfer in both wet and dry environments.

Is XPS foam environmentally friendly?

XPS foam is 100% recyclable and contributes enormously to reducing energy use, making it very eco-friendly. Once installed in a cold storage facility, it lasts decades and significantly lowers the carbon footprint of the building over its lifespan.

Does XPS foam prevent condensation problems in cold storage buildings?

XPS foam insulation can withstand moisture and condensation. However, it’s important to include ventilation in the design to prevent excess moisture inside the cold storage facility.

Leave A Comment