Stone wool, or mineral wool, is a versatile, high performance insulation material. It’s distinguishing characteristic is that it is uniquely capable of simultaneously providing thermal, acoustic and fire protection. When specified appropriately, it can generate significant energy savings.

Stone wool can be used for a range of applications including pitched and flat roofs, flooring and external and internal walls. Stone wool is waterproof, vapour-permeable, durable, recyclable, resistant to chemicals and microorganisms, and does not enhance the growth of bacteria and mould.

What is Stone Wool Made From?

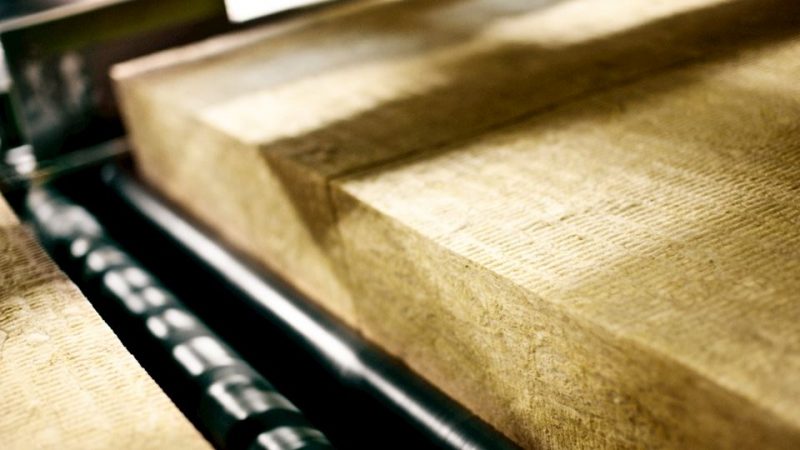

Stone wool is a fibre-based, loose-fill insulation. It has the appearance of wool, however it is stiffer, denser and more fibrous. There are two main types of Stone insulation. The first comes from natural stone fibres such as molten basalt or diabase. This type of stone wool is sourced from volcanic rock. This rock is melted, processed and then spun into “wool” and bound together by different resins and oils.

The second is made from spinning slag. Slag is a byproduct resulting from the production of steel. Manufacturers can also make it from natural rock or a combination of molten slag, natural rock and even glass. Both types of stone wool are typically sold in batts and as loose-fill. Typically, mineral or stone insulation contains up to 90% recycled content.

Stone Wool Production Process

Raw materials used for the production of stone wool include volcanic stones such as diabase, dolomite and basalt as well as briquettes and cement. Major chemical compounds in the composition of those materials are oxides of silicon, aluminium, calcium, magnesium and iron.

- The production process for stone wool begins with placing raw materials in a cupola furnace where they are melted at a temperature above 1400°C. Coke is used as a fuel during this melting process. Oil is also added to incinerate flue gasses

- The melted mass is then brought to the wheels of a centrifuge where it gets unravelled into fibres. The centrifuge wheels break the mass into drops while air is blown to stretch the drops into fibres. As the mass becomes a mist of yarn, the fibres are blown into a collecting chamber.

- Primary felt then reaches a wool precipitation system – the so-called pendulum system that enables achieving excellent insulation characteristics by providing a uniform distribution of fibers and high level of their intertwinement, thus providing more space for »air retention«, which is one of the most important conditions for insulation material functioning

- In the polycondensation chamber, the process of polycondensation or binder fixing is carried out which together with fiber binding provides technical characteristics of the product. The process is carried out at 270°C with water evaporation and fixing of the binder added in the mass unravelling phase. All flue gasses are incinerated and purified, thus closing the circle of flue gas release.

- The chamber process is followed by cutting of final products in to required dimensions, their stacking and packaging.

Benefits of Stone Wool

Stone wool creates an incredibly effective insulation that is easy to use. It installs like any batt insulation in the wall cavity, but it can be either flexible or rigid, delivering a variety of solutions to match different needs. Key benefits of stone wool includes:

- Fire resistance – Stone wool is safer than other insulation types in one important way – it’s typically much more resistant to fire. So, if a fire starts, it will delay the spread.

- Sound insulation – Stone wool is excellent at absorbing sound. This makes it great for dampening sound throughout buildings and creating sound barriers in homes between bathrooms and bedrooms, and in noisier spaces like living rooms or media rooms.

- Moisture repelling – Stone wool naturally repels water and moisture, so the long-term thermal performance of the insulation is not affected by water. Damp and mould can affect your home’s structural integrity, have a detrimental effect on its thermal performance, and compromise the respiratory health of its occupants.

Technonicol Stone Wool Supplied by Plastek

Technonicol produces premium quality stone wool insulation for roofing, walls/facades as well as special applications. The fibrous structure of Technonicol stone wool products ensures excellent acoustic and sound-absorbing properties of the material.

At Plastek, we have extensive experience consulting and supplying Technonicol insulation products, helping to optimise projects by specifying and supplying the ideal solution. We can recommend the right insulation product for your specific project, ensuring a functional and high-performance solution

Related Questions

Does stone wool contain VOCs?

One of the historical pitfalls of stone wool in the past is that it has been that it typically contained a binder to hold the fibres together. These binders used to use chemicals that contained volatile organic compounds like formaldehyde. The insulation would then off-gas these chemicals. This off-gassing ends up being dangerous for anyone installing the product and negatively impacts indoor air quality.

In recent years, VOCs are less of a concern since there’s been a general move in the industry towards using low or no VOC binders, mitigating those pitfalls. Unfortunately, they’re still around, so you need to pay attention when picking your stone wool products. Technonicol stone wool is free of VOCs.

Is stone wool environmentally friendly?

Stone wool insulation is mostly sourced from natural, renewable, or recyclable materials. The steel and iron ore industry produce millions of pounds of slag each year. Instead of sending that material to landfills, it can be recycled into high-performance insulation. Stone wool is produced using a virtually inexhaustible natural resource. The earth makes 38,000 times more rock every year through volcanic and oceanic activity.

Is stone wool dangerous to breathe?

The dust from stone wool can irritate the skin and eyes if a person comes into direct contact with it. Gloves and goggles should be worn when working with the insulation material. However, stone wool is not as harmful to breathe in as asbestos because the fibres are short and thick, meaning the body can easily expel them.

Leave A Comment